The groundnut oil industry is a great chance for entrepreneurs to dive into the vegetable oil market. Groundnut, or peanut oil, is a versatile oil used in cooking, cosmetics, and industry. With the world's population growing, the need for good cooking oils is higher than ever.

Groundnut oil is loved for its mild taste, high smoke point, and health benefits. It's a favorite for those who want healthy and tasty food. Its special qualities also make it important in making personal care and industrial products. This opens up more chances for groundnut oil makers.

Key Takeaways

- Groundnut oil is a versatile and widely-used edible oil with growing demand in the cooking, cosmetic, and industrial sectors.

- The global population growth is driving the need for affordable and high-quality cooking oils, fueling the peanut oil production and processing industry.

- Groundnut oil is renowned for its mild flavor, high smoke point, and rich nutritional profile, making it a popular choice among consumers.

- The oil's unique properties also make it a valued ingredient in the manufacturing of various personal care and industrial products.

- Entrepreneurs can capitalize on the expanding market opportunities in the groundnut oil industry by starting their own peanut oil production and processing business.

Understanding the Groundnut Oil Industry Overview

The groundnut oil market has seen steady growth in recent years. This is due to the growing demand for high-quality vegetable oils worldwide. Groundnut oil, also known as peanut oil, is gaining popularity. It's favored by health-conscious consumers for its nutritional value and versatility in cooking.

Current Market Demand and Growth Potential

Industry analysts predict the global groundnut oil market will keep growing. It's expected to expand at a 5% compound annual growth rate (CAGR) from 2023 to 2028. By 2028, the market could reach over $12 billion. This growth is driven by its increasing use as a healthy cooking oil and in food and cosmetic industries.

Key Players in the Market

The groundnut oil industry is led by several major players. These include:

- Cargill, Incorporated

- Archer Daniels Midland Company

- Wilmar International Limited

- Bunge Limited

- Adani Wilmar Limited

- Ruchi Soya Industries Limited

These leaders have strong distribution networks and advanced processing technologies. They also have well-known brands, helping them dominate the global market.

"The groundnut oil industry is experiencing a surge in demand as consumers increasingly prioritize health and sustainability in their purchasing decisions. This trend has created numerous growth opportunities for established players and new market entrants alike."

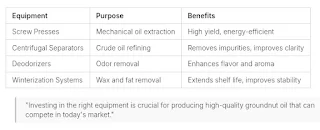

Essential Equipment for Groundnut Oil Production

Making top-notch groundnut oil needs special tools and machinery. From getting the oil out to making it pure, the right gear is key. It boosts yield, efficiency, and quality. Let's look at the must-have equipment for making groundnut oil:

Oil Extraction Machinery

The core of making groundnut oil is the oil press. These machines use force to get oil from groundnut kernels. Modern oil presses, like screw and hydraulic presses, get lots of oil. They also keep the oil's natural taste and nutrients.

Filtration and Refining Systems

After getting the oil, it must be cleaned up. This makes it clearer and more stable. Groundnut oil needs various filters, like gravity, centrifuges, and membrane filters. These tools take out bad stuff, making the oil better.

Technological Advancements

The groundnut oil world has seen big tech leaps. Oil mill technology now has better automation, energy use, and control. Groundnut processing equipment like deodorizers and winterizers also improve the oil. They get rid of bad smells and extend shelf life.

Using the best oil extraction machinery and gear, producers can do better. They get more oil, make it better, and stay on top.

Initial Investment and Business Planning

Starting a groundnut oil business needs good financial planning and a solid groundnut oil business plan. The costs to begin can change a lot. This depends on how big your operation is, what equipment you need, and the local market.

Capital Requirements and Funding Options

Starting a groundnut oil mill takes a lot of money. You'll need to buy or rent land, build or fix a facility, get machinery, and stock up. The startup costs can be from tens of thousands to millions of dollars.

To fund your groundnut oil business, look at loans, angel investors, or crowdfunding. Knowing about oil mill financing can help you choose the best way to fund your business.

Creating a Viable Business Plan

Make a detailed groundnut oil business plan. It should cover market analysis, production strategy, financial forecasts, and growth goals.

Find out who your target market is, who your competitors are, and what makes your oil special.

Describe how you'll make your oil, from getting quality groundnuts to using the right equipment and hiring staff.

Include financial forecasts. This should cover start-up costs, ongoing expenses, sales predictions, and expected returns on investment (ROI).

Financial Projections and ROI Analysis

It's important to accurately predict your financial future. This is key for getting funding and keeping your business going. Look at the return on investment (ROI) from making groundnut oil. Consider production costs, market prices, and how much you'll sell.

Sourcing Quality Groundnuts for Production

Getting a steady supply of top-notch groundnuts is vital for making premium groundnut oil. As a producer, it's important to build strong ties with groundnut suppliers. This ensures a constant flow of raw materials all year.

Knowing the peanut cultivation cycle and seasonal changes is crucial. Groundnuts are usually picked in autumn. So, producers need to plan early to have enough stock for all year.

Develop partnerships with local groundnut farmers to secure exclusive access to their crops.

Stay informed about weather patterns and other factors that may impact groundnut yields in your region.

Invest in climate-controlled storage facilities to maintain the freshness and quality of your raw material procurement.

By spreading out your groundnut supplier network and using smart raw material procurement strategies, you can avoid supply chain problems. This ensures you always have the best groundnuts for your oil making.

"Establishing strong relationships with reliable groundnut suppliers is key to ensuring a steady flow of raw materials throughout the year."

Setting Up Your Production Facility

Starting a groundnut oil business needs careful planning. You must choose the right location and design your factory well. Also, having good storage solutions is key to success.

Location Selection Criteria

Finding the right spot for your oil mill is very important. Look for places that are close to where groundnuts are grown. They should also be easy to get to by road, rail, or sea.

Make sure the area has the basic services like electricity, water, and waste management. It must also follow local laws and protect the environment.

Factory Layout and Design

Your factory's layout should be efficient, safe, and able to grow. Set aside areas for each main task, like cleaning and sorting groundnuts, crushing, refining, and packaging.

Make sure the path for materials and people is clear. This helps avoid delays and keeps things running smoothly.

Storage Requirements

Good storage is vital for keeping groundnuts and oil fresh. You need places that control the climate for storing raw groundnuts and oil.

Also, have a system for keeping track of your oil products. This helps you manage your stock well.

By focusing on these important steps, you can build a groundnut oil mill. It will be efficient, growable, and ready for the market's needs.

Groundnut Business, Vegetable Oil Mills Operations

Running a successful groundnut oil mill needs focus on making things better, quality control, and following the best practices. Good oil mill management is key to making more and keeping quality high.

First, having a smooth production flow is vital. This means keeping equipment in top shape, handling raw materials well, and making the process smooth. Regular checks and upkeep can cut down on stops and keep quality up.

Quality control is also crucial for a thriving groundnut oil business. Using strict tests from start to finish ensures quality meets standards. Investing in top lab gear and training staff boosts production efficiency and operational best practices.

Step-by-Step Oil Production Process

Making high-quality groundnut oil is a detailed process. It starts with cleaning and sorting and ends with refining and filtering. Each step is important for the oil's purity and quality. Let's explore the main steps of groundnut oil extraction methods, oil refining process, and oil production techniques.

Cleaning and Sorting

The first step is cleaning and sorting the raw groundnuts. This removes any unwanted materials and damaged nuts. It makes sure the nuts are clean and ready for the next steps. Advanced sorting tools, like optical scanners, help pick the best nuts for better oil quality.

Crushing and Extraction

After cleaning, the nuts are crushed and the oil is extracted. Special machines are used for this. The oil production techniques used here affect the oil's quality and amount.

Refining and Filtering

The last step is refining and filtering the oil. The oil goes through several processes to remove impurities. This includes degumming, neutralization, bleaching, and deodorization. The oil refining process makes sure the oil is safe and of high quality, ready for sale.

"The key to producing high-quality groundnut oil is the attention to detail in every step of the production process."

Quality Control and Safety Standards

Keeping a tight grip on quality control and following food safety regulations is key in the groundnut oil world. A strong HACCP (Hazard Analysis and Critical Control Points) program is vital. It makes sure the oil is safe and pure.

It's important to test the oil quality often. This means checking its physical and chemical makeup. Things like acidity levels and the presence of contaminants are checked. This way, producers can ensure their oil is always top-notch and safe.

- Establish a HACCP-based food safety management system

- Implement regular testing for parameters like free fatty acids, peroxide value, and moisture content

- Ensure compliance with local and international food safety regulations

- Maintain detailed records of all quality control procedures and test results

- Train employees on proper handling, storage, and transportation protocols

By focusing on quality control and safety standards, groundnut oil makers can stand out. They earn trust from consumers and set themselves up for success in a tough market.

"Consistently delivering high-quality, safe groundnut oil is not just a competitive advantage – it's a moral and legal obligation."

Packaging and Labeling Requirements

When marketing groundnut oil, packaging and labeling are key. Good oil packaging solutions keep your oil fresh and create a strong brand. This makes your product stand out to customers.

Packaging Materials Selection

Choosing the right packaging for your groundnut oil is vital. You can use glass bottles, plastic containers, or tin cans. Each has its own benefits and drawbacks, like cost, durability, and shelf life. Pick the best option for your market and production.

Legal Labeling Guidelines

Following food labeling regulations is essential for safety and compliance. Your labels must show the product name, weight, ingredients, and nutritional info. Also, add your logo and product message to boost product branding and recognition.

Marketing and Distribution Strategies

Effective marketing and distribution are crucial for your business's success. By creating strategic marketing campaigns and setting up strong distribution channels, you can reach your target consumers and boost sales.

Branding and Advertising

Create a strong, recognizable brand for your groundnut oil products. Invest in professional packaging design and logo development. Use consistent branding across all marketing materials. Use digital marketing, print media, and in-store promotions to raise awareness and promote your groundnut oil marketing.

Distribution Partnerships

Form partnerships with reputable wholesalers, retailers, and online marketplaces. This will help you expand your distribution channels and reach more people. Negotiate good terms, like exclusive distribution rights or volume discounts, to increase your reach and profits.

Targeted Promotions

Develop targeted promotional strategies to boost brand promotion and sales. This could include in-store sampling, loyalty programs, or seasonal discounts. Use customer data and market trends to tailor your promotions and engage your target audience effectively.

Comments

Post a Comment